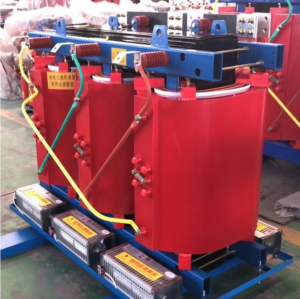

Product overview

Designed specifically for medium-sized industrial facilities and large-scale commercial complexes, the 1500kVA oil-immersed transformer achieves a perfect balance between power density and operational efficiency. It adopts a modular intelligent cooling system and a digital monitoring architecture, providing a solid energy guarantee for continuous production and operation.

Main technical Parameter

| Rated capacity | 1500 KVA |

| Primary voltage | 33KV/35KV/13.2KV/11KV/10KV/6.3KV/6KV(customizable) |

| Tap changer | ±2*2.5/±5 |

| Secondary voltage | 400V/415V/433V/380V(customizable) |

| Vector group | Dyn11/Yzn11/Yyn0 |

| Number of phase | Three phase |

| frequency | 50hz |

| Temperature rise | 65K |

| Short circuit impedance | 4.0% |

| No load loss | Different series(S10,S11,S13,S14),got different loss data |

| Load loss 75ºC | Different series(S10,S11,S13,S14),got different loss data |

| Cooling type | ONAN |

| Oil type | 25#/45# |

| standards | IEC 60076-1 |

The Development History of 1500KVA Transformer: From Invention to Practical Application

Transformers are core equipment in AC power systems that realize voltage conversion, impedance matching, and electrical isolation. Their invention and evolution are closely linked to the popularization of alternating current, and the development process can be divided into the following key stages:

- Pre-invention Theoretical Foundation (1831–1880s)

The birth of transformers relies on the discovery of electromagnetic induction principle. In 1831, British scientist Michael Faraday demonstrated the phenomenon of electromagnetic induction through experiments: changing magnetic flux in a closed coil can induce an electromotive force. This laid the fundamental theoretical basis for the design of transformers.

In the following decades, scientists carried out preliminary explorations on “mutual induction” applications. However, early devices were only laboratory prototypes with low efficiency and large energy loss, and could not be applied to actual power transmission scenarios. At that time, the power industry was in the “DC vs AC” controversy—direct current (advocated by Edison) was difficult to transmit over long distances due to large line losses, while alternating current (supported by Tesla and Westinghouse) was naturally compatible with voltage conversion, creating an urgent demand for transformers.

- Preliminary Invention and Prototyping (1880s)

The first transformer prototype close to the modern structure was born in the 1880s, with multiple inventors making breakthroughs almost simultaneously:

In 1882, French engineer Gustave Trouvé developed a small mutual induction device, which realized the conversion between low voltage and high voltage for the first time, and was regarded as the earliest prototype of transformers.

In 1885, Hungarian engineers Zipernowsky, Bláthy and Déri from the Ganz Works designed the “ZBD transformer”—the first transformer with a closed iron core structure. This design greatly reduced magnetic flux leakage and improved energy conversion efficiency, marking the transition of transformers from laboratory to practical use. The ZBD transformer was first used in the electric lighting system in Budapest, Hungary, successfully supplying power to street lamps through AC voltage boosting and reducing line loss during transmission.

- Industrialization and Large-scale Application (1890s–1900s)

The commercialization of transformers was promoted by the Westinghouse Electric Company in the United States. After acquiring Tesla’s AC patent, Westinghouse improved the ZBD transformer design and applied it to the world’s first large-scale AC power station—the Niagara Falls Power Station completed in 1895.

This project used transformers to boost the generated electricity to 11,000 volts for long-distance transmission, and then reduced the voltage to the user level through step-down transformers, successfully transmitting power to Buffalo, 35 kilometers away. This practice verified the feasibility of long-distance AC power transmission, completely reversing the disadvantage of alternating current in the “current war” and promoting the global popularization of AC power systems.

During this period, transformers began to be mass-produced, with core materials gradually evolving from cast iron to silicon steel sheets (invented in 1903). Silicon steel sheets have high magnetic permeability and low eddy current loss, which significantly improved the efficiency of transformers and laid the foundation for the development of modern transformers.

- Technological Improvement and Standardization (20th Century)

The 20th century witnessed the continuous optimization of transformer technology and the establishment of industry standards:

Material Innovation: In the early 20th century, oil-immersed structure became mainstream—transformer oil was used as both insulating medium and cooling medium, which improved insulation performance and heat dissipation efficiency. Later, new materials such as epoxy resin were applied to dry-type transformers, expanding the application scenarios of transformers in fire-proof places.

Structural Optimization: The design of transformers developed towards compactness and high efficiency. Manufacturers optimized winding structure, core lamination process (such as staggered lamination) and cooling system (natural oil circulation, forced oil circulation, etc.) to reduce volume and energy loss.

Standardization Construction: International Electro technical Commission (IEC) issued the IEC 60076 series standards for transformers, and countries formulated corresponding national standards (such as ANSI C57 in the United States, GB 1094 in China). These standards unified technical parameters such as transformer capacity, voltage level, loss index and test methods, promoting the global circulation of transformer products.

Functional Expansion: With the development of power electronics technology, special transformers emerged, such as rectifier transformers for industrial electrolysis, arc furnace transformers for metallurgy, and instrument transformers for measurement and protection, meeting the diversified needs of different industries.

- Modern Intelligent Development (Late 20th Century–Present)

Since the late 20th century, transformers have stepped into the era of intelligence and digitization:

Digital Monitoring System: Modern transformers are equipped with sensors to monitor operating parameters such as oil temperature, winding temperature, load current, and partial discharge in real time. The data is transmitted to the background through the Internet of Things (IoT) technology, realizing remote fault diagnosis and predictive maintenance.

High-efficiency and Energy-saving Technology: The promotion of energy-efficient transformers (such as IEC Level 1 energy efficiency products) has reduced no-load loss and load loss, in line with the global energy conservation and emission reduction trend. Amorphous alloy cores are widely used in small and medium-capacity transformers, further reducing no-load loss by 60%~80% compared with silicon steel cores.

Green and Environmentally Friendly Design: Environmentally friendly transformer oils (such as natural ester oils) replace traditional mineral oils, reducing environmental pollution risks. Meanwhile, the recyclability of transformer materials is improved to meet the requirements of circular economy.

- Summary of Development Significance

From the initial laboratory prototype to the modern intelligent transformer, this equipment has not only solved the problem of long-distance AC power transmission, but also become the cornerstone of the modern power grid. Its development has promoted the popularization of electricity, driven the industrialization process of various countries, and laid the foundation for the operation of modern society such as industry, commerce and residential electricity consumption.