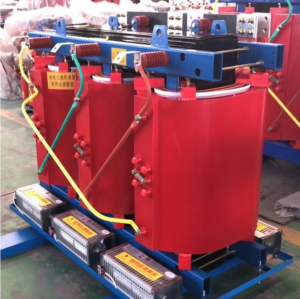

Product overview

As a leading manufacturer of power distribution transformer, QIANLAI proudly present our 2000kVA oil immersed transformer—a robust, energy-saving solution engineered for demanding industrial, commercial, and utility power distribution systems. This oil immersed transformer complies with global standards like IEC 60076, IEEE C57, , delivering unrivaled reliability, low operational losses, and long service life, making it the preferred choice for grid upgrades, manufacturing plants, and critical infrastructure projects worldwide.

Main technical Parameter

| Rated capacity | 2000 KVA |

| Primary voltage | 33KV/35KV/13.2KV/11KV/10KV/6.3KV/6KV(customizable) |

| Tap changer | ±2*2.5/±5 |

| Secondary voltage | 400V/415V/433V/380V(customizable) |

| Vector group | Dyn11/Yzn11/Yyn0 |

| Number of phase | Three phase |

| frequency | 50hz |

| Temperature rise | 65K |

| Short circuit impedance | 4.0% |

| No load loss | Different series(S10,S11,S13,S14),got different loss data |

| Load loss 75ºC | Different series(S10,S11,S13,S14),got different loss data |

| Cooling type | ONAN |

| Oil type | 25#/45# |

| standards | IEC 60076-1 |

Partial Discharge of 2000KVA transformer

Partial discharge (PD) in oil-immersed transformers refers to non-penetrating discharge initiated by electric field concentration in local areas of insulation. It serves as an early warning signal of insulation degradation. If left unchecked over the long term, it will lead to insulation breakdown and equipment failure, necessitating full-cycle management covering mechanism analysis, detection, and prevention & control. Below are the core points:

- Core Definition & Mechanism

Partial discharge is a phenomenon where localized weak points in an insulation structure discharge first under voltage application without causing penetrating breakdown. It commonly occurs in areas with concentrated electric fields, such as air gaps, oil gaps, electrode sharp corners, and oil-paper interfaces. Its core mechanisms are as follows:

- Electric Field Distortion Bubbles, impurities, and structural defects cause the local electric field strength to far exceed the average level. The dielectric strength of gas is only 1/10 to 1/100 that of oil/paper, making it prone to discharge first.

- Dielectric Property Difference Air gaps have low dielectric constants. Under alternating current (AC) voltage, they bear a higher proportion of the electric field intensity, which significantly lowers the inception discharge voltage.

- Vicious Cycle Active substances (e.g., ozone, nitrogen oxides) and local overheating generated by discharge accelerate insulation aging, producing more bubbles and defects, which further intensify partial discharge.

- Typical Types & Locations

| Discharge Type | Typical Locations | Causes | Hazards |

| Bubble Discharge | Bubbles in oil, cavities in solid insulation, residual bubbles from improper vacuum oil filling | Electric field concentration due to dielectric constant differences | Sustained erosion of insulation, reduction of breakdown voltage |

| Surface Discharge | Oil-paper interfaces, insulation board surfaces, oil wedges at winding ends | Charge accumulation and electric field distortion at interfaces | Prone to developing into flashover, damaging the integrity of insulation |

| Floating Potential Discharge | Loose metal components, tap changer forks, poor grounding of magnetic shields | Suspended potential of components creates potential difference with surrounding areas | Generates pulse current, damages insulation, and interferes with monitoring |

| Electrode Tip Discharge | Burrs on winding conductors, sharp corners of lead joints, defects in grading rings | Concentrated electric field at tips | Triggers corona discharge, accelerates oil cracking and insulation aging |

| Impurity Discharge in Oil | Moisture, fibers, and metal particles in oil | Polarization of impurities leads to multiplication of local electric field strength | Forms conductive channels, inducing insulation breakdown |

III. Main Hazards

- Insulation DegradationActive substances and local overheating from discharge accelerate the aging of oil-paper insulation, reducing its mechanical and electrical strength.

- Pre-fault IndicatorSudden changes in PD magnitude often indicate the expansion of internal defects, serving as an early signal of winding deformation and tap changer malfunctions.

- Accident RiskLong-term accumulation will result in insulation breakdown, leading to severe accidents such as winding short circuits and tank explosions.

IV. Key Prevention & Control Measures

1.Manufacturing Process Control

♦Vacuum drying of insulation parts and vacuum impregnation of windings to avoid residual bubbles.

♦Deburring of conductors and optimized design of grading rings to reduce electric field concentration at tips.

♦Strict control of moisture content (≤10ppm) and particle count in oil, adopting multi-stage filtration and vacuum oil filling.

2.Operation & Maintenance Management

♦Regular DGA testing, monitoring the growth trends of H₂ and C₂H₂, and establishing a baseline database.

♦Installation of HFCT/ultrasonic online monitoring systems to track PD magnitude and discharge patterns in real time.

♦Prevention of overvoltage impacts by configuring surge arresters and overvoltage protection devices.

3.Fault Handling Procedures

♦When PD magnitude exceeds the standard, comprehensively locate defects by combining DGA, ultrasonic, and pulse current methods.

♦For bubble/moisture issues: Implement hot oil circulation, vacuum degassing, and insulation oil replacement.

♦For structural defects: Repair loose components, fix winding deformation, and replace aged insulation parts.

♦Put the transformer into operation only after passing re-testing, and establish a fault file to optimize the maintenance cycle.