Product overview

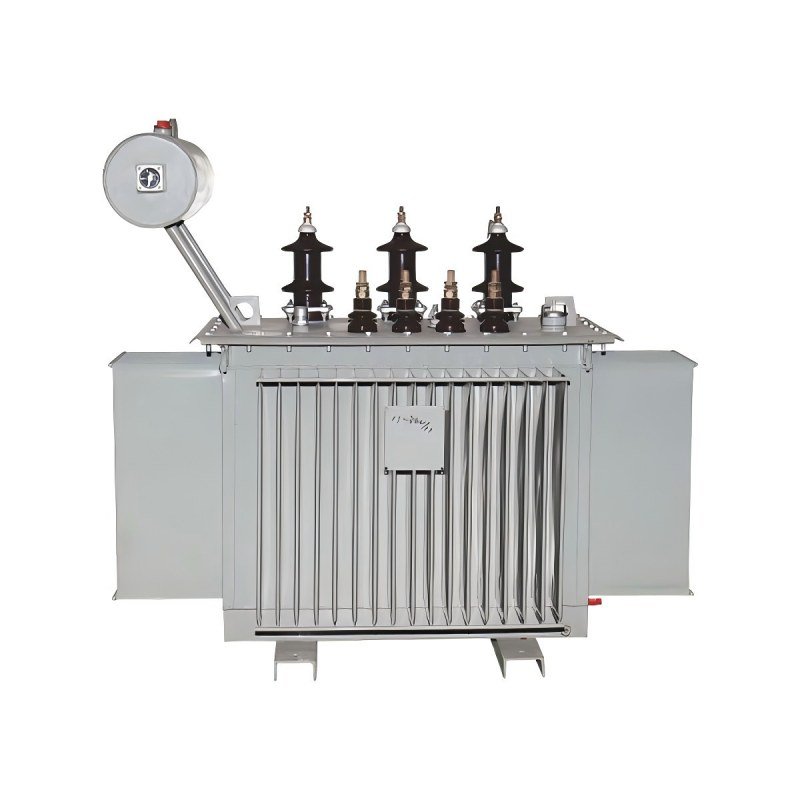

750kVA oil immersed transformer manufactured by QIANLAI ELECTRIC adopts industry-leading technologies and is specially designed for power distribution systems in industrial, commercial and utility sectors.

This three-phase oil-immersed transformer delivers outstanding energy efficiency, reliable power transmission and a long service life, meeting the stringent power application requirements across the globe.

Main technical Parameter

| Rated capacity | 750 KVA |

| Primary voltage | 33KV/35KV/13.2KV/11KV/10KV/6.3KV/6KV(customizable) |

| Tap changer | ±2*2.5/±5 |

| Secondary voltage | 400V/415V/433V/380V(customizable) |

| Vector group | Dyn11/Yzn11/Yyn0 |

| Number of phase | Three phase |

| frequency | 50hz |

| Temperature rise | 65K |

| Short circuit impedance | 4.0% |

| No load loss | Different series(S10,S11,S13,S14),got different loss data |

| Load loss 75ºC | Different series(S10,S11,S13,S14),got different loss data |

| Cooling type | ONAN |

| Oil type | 25#/45# |

| standards | IEC 60076-1 |

Insulation System of 750 KVA Oil Immersed Transformer

The insulation system of oil-immersed transformers is core to safe operation, isolating components at different potentials to prevent breakdown and leakage. It adopts a liquid-solid composite structure with transformer oil as the core medium, divided into main insulation and longitudinal insulation.

- Core Insulation Media

Transformer Oil: Serves both insulation and heat dissipation. Key requirements: breakdown voltage ≥35kV, water content ≤30ppm, acid value ≤0.03mgKOH/g. Common types: mineral oil; environmentally friendly ester oils for high-end scenarios.

Solid Insulating Materials: Include insulating paperboard (for spacers, end rings), insulating paper (for turn-to-turn/layer-to-layer insulation), epoxy products (for bushings, tap changers), and fiberglass binding tapes, ensuring mechanical support and enhanced insulation.

- Core Insulation Structure

Main Insulation: Isolates components at different potentials, including inter-winding (HV-LV), winding-to-core/tank, and lead insulation. Adopts oil gap-paperboard composite structure; bushings insulate leads passing through the tank wall.

Longitudinal Insulation: Protects the interior of windings, including turn-to-turn (insulating paper), layer-to-layer (insulating paperboard), and section-to-section insulation, preventing internal partial discharge.

III. Key Insulation Components

- Bushings (HV/LV, with oil/epoxy insulation)

- Tap changers (oil-resistant epoxy insulation for contacts/bases)

- Oil tanks (insulating paint/gaskets, reliable grounding to avoid floating potential discharge)

- Aging & Maintenance

- Aging causes: oil oxidation, solid insulation moisture/heat aging, partial discharge.

- Maintenance: regular oil quality testing (filtration/oil change if needed), monitoring winding insulation resistance, and keeping top oil temperature ≤95℃.

- Standard Requirements

- Complies with GB 1094.3-2017 and IEC 60076-3, passing power frequency withstand voltage, lightning impulse, and partial discharge tests.